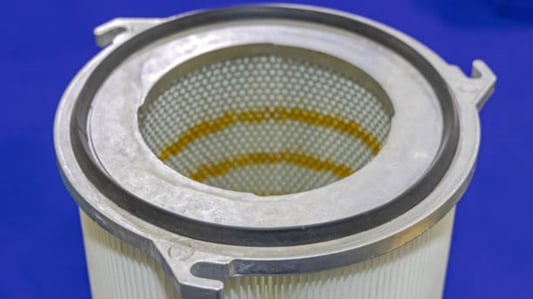

What is a boge oil separator and Why is it Important?A Boge oil separator is a crucial component in many industrial machinery systems. It plays a vital role in separating oil from compressed air, ensuring that the air remains clean and free from contaminants. This article will explore the various aspects of a Boge oil separator and highlight its significance in maintaining the efficiency and longevity of machinery.Efficient Oil Separation for Optimal PerformanceOne of the primary functions of a Boge oil separator is to efficiently remove oil from compressed air. This is essential because oil can have detrimental effects on machinery if it enters sensitive components. By effectively separating oil from the air, the Boge oil separator prevents any potential damage or malfunctions, ensuring optimal performance and extending the lifespan of the machinery.Preventing Contamination and Enhancing Air QualityContaminated air can lead to a variety of issues in industrial processes. It can affect the quality of products, damage equipment, and even pose health risks to workers. A Boge oil separator plays a crucial role in preventing such contamination by removing oil and other contaminants from the compressed air. This helps maintain a clean and healthy working environment, ensuring the safety and well-being of everyone involved.Reducing Maintenance and DowntimeRegular maintenance and unexpected downtime can be costly for any industrial operation. The presence of oil in compressed air systems can significantly contribute to increased maintenance needs and unplanned shutdowns. By utilizing a Boge oil separator, the amount of oil entering the system is minimized, reducing the frequency of maintenance requirements and the risk of unplanned downtime. This ultimately leads to improved productivity and cost savings for the business.Extending the Lifespan of MachineryIndustrial machinery is a significant investment, and maximizing its lifespan is essential for optimizing returns. A Boge oil separator helps in achieving this goal by preventing oil from reaching critical components of the machinery. Oil can cause corrosion, wear, and damage, leading to premature failure and costly repairs. By using a Boge oil separator, machinery owners can significantly extend the lifespan of their equipment, saving money in the long run.Enhancing Energy EfficiencyEnergy efficiency is a key concern for many industries. Compressed air systems are known to be energy-intensive, and any inefficiencies can lead to increased operational costs. A Boge oil separator aids in enhancing energy efficiency by reducing the oil content in the compressed air. When the air is free from oil, it can flow more smoothly, reducing friction and pressure drops. This results in improved energy efficiency and reduced energy consumption, translating into significant cost savings over time.Meeting Regulatory Standards and Environmental ComplianceMany industries are subject to strict regulatory standards and environmental compliance requirements. Clean air is often a vital aspect of these regulations. By incorporating a Boge oil separator into their machinery systems, businesses can ensure that their operations meet these standards. The oil separator effectively removes oil and contaminants, enabling companies to fulfill their legal obligations and contribute to a cleaner and healthier environment.Easy Installation and MaintenanceBoge oil separators are designed with ease of installation and maintenance in mind. They can be easily integrated into existing compressed air systems without requiring significant modifications. Additionally, the maintenance of these separators is relatively straightforward, with routine inspections and filter replacements being the primary tasks. This user-friendly nature makes Boge oil separators a convenient choice for industrial machinery owners.Various Applications in Different IndustriesThe versatility of Boge oil separators allows them to be used in various industries and applications. From automotive manufacturing to food processing, these separators find application in any industry that utilizes compressed air systems. They can effectively remove oil and contaminants from the air, irrespective of the specific industrial process, making them a valuable asset for a wide range of businesses.Investing in Quality for Long-Term BenefitsWhen it comes to Boge oil separators, investing in quality is crucial. Choosing a reliable and reputable manufacturer ensures that the oil separator will perform optimally and provide long-term benefits. It is essential to consider factors such as efficiency, durability, and warranty when selecting a Boge oil separator, as these factors directly impact the overall effectiveness and lifespan of the machinery.Quote InquiryContact us!