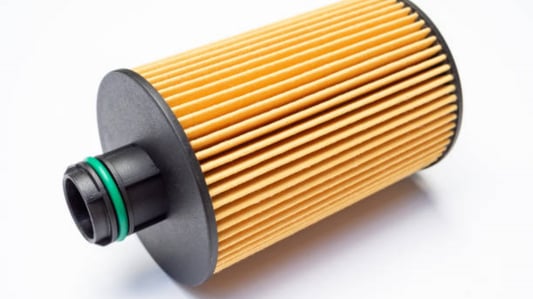

Understanding the Filter Element: A Comprehensive GuideFilters play a crucial role in our daily lives. From the air we breathe to the water we drink, filters help remove impurities and provide us with clean, safe resources. But have you ever wondered what exactly is a filter element? In this article, we will be discussing everything you need to know about filter elements:What is a Filter Element?Simply put, a filter element is the part of a filter that actually performs the filtration process. It is responsible for separating unwanted particles from a fluid or gas stream. Most filter elements are made up of a mesh or membrane that traps contaminants, preventing them from passing through. Depending on the application, filter elements can be made from a variety of materials such as paper, cloth, metal, or polymer. They can also come in different shapes, sizes, and configurations to fit specific needs.How does a Filter Element Work?The filtering process begins when the fluid or gas enters the filter housing. It passes through the filter element, where particles of a certain size are trapped. The clean fluid or gas is then allowed to flow out of the filter. The effectiveness of a filter element is determined by its ability to capture and retain particles. Factors such as the mesh size, material, and configuration can all impact its performance.Why is a Filter Element Important?A filter element is essential for maintaining the quality of fluids and gases. Without it, impurities and contaminants can build up and cause damage to equipment and machinery. It can also pose health risks to those who consume or use the unfiltered resource. For example, a clogged fuel filter in a car can reduce engine performance and potentially cause mechanical issues. Meanwhile, a water filter with a compromised filter element can allow harmful bacteria and parasites to enter the drinking water supply.Types of Filter ElementsThere are several types of filter elements used for different applications:Cartridge Filters: These are cylindrical filter elements that are made up of a perforated core and a filter media layer. They are commonly used in water, air, and gas filtration systems.Bag Filters: These are filter elements made from a high-quality filter cloth that can capture impurities as small as 1 micron. They are often used in industrial applications such as paint booths and chemical processing plants.Pleated Filters: These are filter elements that have a pleated design, allowing for a larger surface area for filtration. They are ideal for high flow rate applications and can be used in many different industries.How to Choose a Filter ElementChoosing the right filter element depends on several factors, including the type of fluid or gas being filtered, the contaminants present, and the desired flow rate. It is essential to select a filter element that is compatible with the filter housing and can withstand the operating conditions.How to Replace a Filter ElementRegular filter element replacement is necessary to ensure optimal performance and prevent equipment damage. The frequency of replacement varies depending on the application and the type of filter. In general, it is recommended to replace the filter element when it becomes clogged or after a certain amount of time has passed. To replace the filter element, follow the manufacturer's instructions and make sure to dispose of the old element properly.Where to Buy Filter ElementsFilter elements can be purchased from various suppliers such as hardware stores, online retailers, and specialty distributors. When selecting a supplier, it is important to ensure they offer quality filter elements that meet the necessary standards and requirements for the application.How to Maintain a Filter ElementProper maintenance is crucial to extend the life of a filter element and ensure its effectiveness. This includes routine inspection, cleaning if necessary, and timely replacement. It is also important to monitor the performance of the filter and replace it immediately if any issues arise.The Future of Filter ElementsThe development of new technologies has led to advancements in filter element design and performance. From nanofiber filtration to smart sensors, innovations continue to emerge that improve the efficiency, durability, and effectiveness of filter elements. As demands for cleaner and safer resources increase, filter elements will play a significant role in meeting these needs.Quote InquiryContact us!