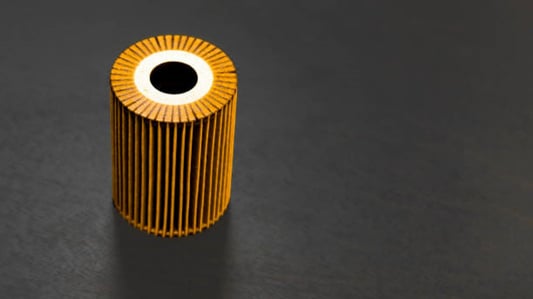

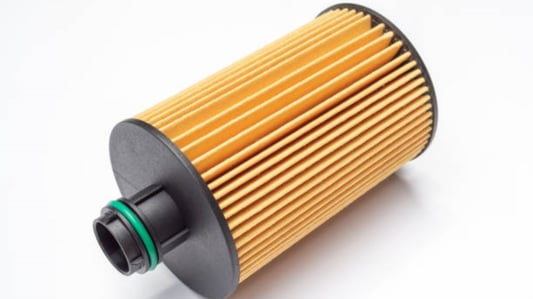

Introduction When it comes to maintaining your vehicle, one of the most important aspects is checking the oil filter. The oil filter is responsible for removing contaminants from the engine oil, which ensures that your engine remains clean and lubricated. A dirty oil filter can lead to a variety of engine problems, which is why it is important to know how to identify a dirty oil filter. In this article, we will explore 10 ways to tell if your oil filter is dirty. Reduced Engine Performance One of the first signs that your oil filter may be dirty is reduced engine performance. A dirty oil filter can cause your engine to work harder, which can lead to reduced power and acceleration. If you notice that your vehicle is not performing as well as it should, it may be time to check your oil filter. Unusual Engine Noises Another sign of a dirty oil filter is unusual engine noises. A dirty oil filter can cause the engine to make knocking or ticking sounds, which can be alarming. If you notice any unusual engine noises, it is important to get your oil filter checked as soon as possible. Oil Pressure Warning Light If your vehicle has an oil pressure warning light, this can also be an indication of a dirty oil filter. A dirty oil filter can cause the oil pressure in the engine to drop, which can trigger the warning light. If you notice this warning light, it is important to check the oil filter as soon as possible. Contaminated Oil A dirty oil filter can also cause the engine oil to become contaminated. You may notice that the oil is darker than usual or has a gritty texture. Contaminated oil can cause serious damage to your engine, so it is important to change your oil filter regularly to prevent this from happening. Excessive Exhaust Smoke If your engine is producing excessive exhaust smoke, this can also be a sign of a dirty oil filter. A dirty oil filter can cause the engine to burn oil, which can lead to smoke coming out of the exhaust. If you notice this, it is important to get your oil filter checked as soon as possible. Slow Engine Response Another sign of a dirty oil filter is slow engine response. A dirty oil filter can cause the engine to respond more slowly when you press down on the accelerator. If you notice a delay in engine response, it may be time to check your oil filter. Engine Stalling A dirty oil filter can also cause your engine to stall. This can be a dangerous situation if it happens while you are driving, so it is important to get your oil filter checked as soon as possible. Higher Oil Consumption If you notice that your vehicle is using more oil than usual, this can also be a sign of a dirty oil filter. A dirty oil filter can cause the engine to use more oil, which can be costly and inconvenient. If you notice higher oil consumption, it is important to get your oil filter checked. Oil Filter Appears Dirty Finally, one of the most obvious signs of a dirty oil filter is if it appears dirty. If you remove the oil filter and it appears clogged or covered in debris, it is time to change it. Conclusion In conclusion, a dirty oil filter can cause a variety of engine problems, which is why it is important to know how to identify a dirty oil filter. By checking for reduced engine performance, unusual engine noises, an oil pressure warning light, contaminated oil, excessive exhaust smoke, slow engine response, engine stalling, higher oil consumption, and a dirty oil filter, you can keep your vehicle running smoothly. Remember to change your oil filter regularly to prevent these issues from occurring. dirty oil filter, engine performance, engine noises, oil pressure warning light, contaminated oil, excessive exhaust smoke, slow engine response, engine stalling, oil consumption, clogged filterHow to Identify a Dirty Oil Filter: 10 Signs to Look ForIs your engine not performing as well as it should? It may be time to check your oil filter. Read on for 10 signs of a dirty oil filter and how to identify them.Quote InquiryContact us!