Efficiently Separating Air and Oil for Enhanced Performance: The Ingersoll Rand Air Oil Separator

Air compressors play a crucial role in various industrial applications, providing a reliable source of compressed air for powering tools and equipment. However, during the compression process, oil can mix with the compressed air, leading to potential contamination and reduced efficiency. To address this issue, Ingersoll Rand, a renowned manufacturer of industrial equipment, offers the Ingersoll Rand Air Oil Separator – a vital component that efficiently separates air and oil, ensuring optimal performance and maintaining the purity of compressed air.

1. Understanding the Ingersoll Rand Air Oil Separator

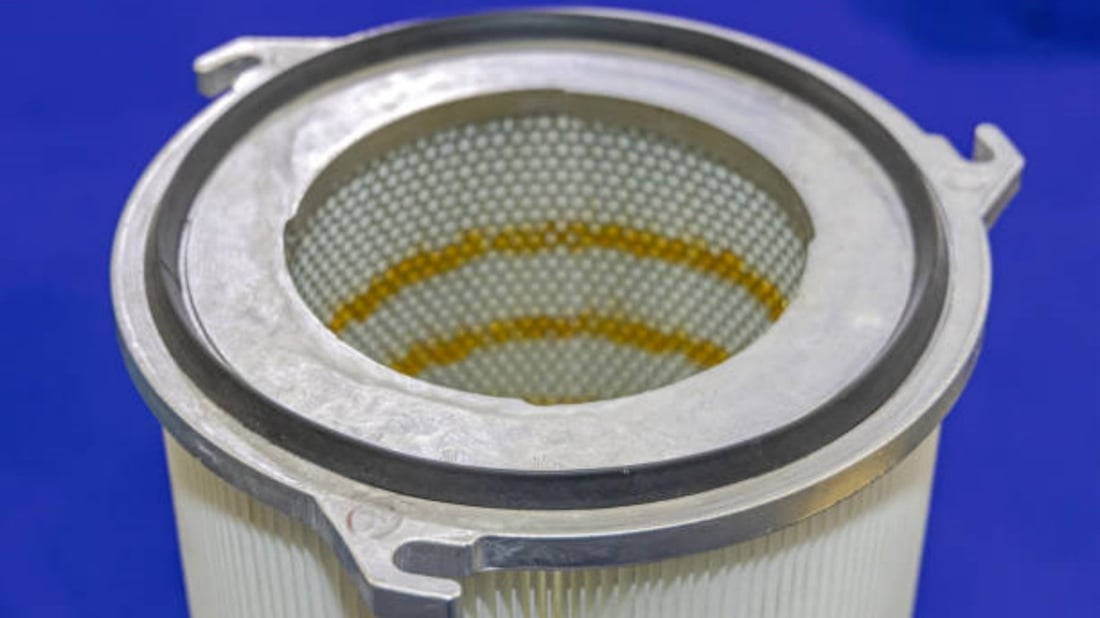

The Ingersoll Rand Air Oil Separator is a specialized filtration system designed to separate oil aerosols from compressed air, ensuring clean and oil-free air supply. It is an essential component of air compressors, particularly those used in critical applications where oil contamination can lead to equipment malfunction or product quality issues.

2. Functioning Principles of the Ingersoll Rand Air Oil Separator

The Ingersoll Rand Air Oil Separator operates on the principle of coalescence. As compressed air containing oil aerosols passes through the separator, the unique design and filtration media of the separator allow the oil droplets to coalesce, forming larger droplets. These larger droplets then separate from the air stream due to gravity, allowing clean air to pass through for further use.

3. Benefits of Using the Ingersoll Rand Air Oil Separator

By incorporating the Ingersoll Rand Air Oil Separator into your air compressor system, you can enjoy numerous benefits:

- Enhanced Equipment Performance: The separator ensures that the compressed air is free from oil contamination, preventing damage to sensitive pneumatic equipment and improving overall performance.

- Extended Equipment Lifespan: By removing oil aerosols from the compressed air, the separator helps prevent wear and tear on equipment components, resulting in increased lifespan and reduced maintenance costs.

- Improved Product Quality: Oil contamination in compressed air can lead to product defects and contamination in various manufacturing processes. The use of the separator ensures clean air supply, maintaining product quality and reducing the risk of production issues.

- Energy Efficiency: Clean air free from oil aerosols reduces friction and pressure drops in pneumatic systems, leading to energy savings and lower operational costs.

4. Choosing the Right Ingersoll Rand Air Oil Separator

When selecting an Ingersoll Rand Air Oil Separator for your air compressor system, it is essential to consider factors such as the compressor model, flow rate, and specific application requirements. Ingersoll Rand offers a range of separators tailored to different compressor models and capacities, ensuring compatibility and optimal performance.

5. Installation and Maintenance of the Ingersoll Rand Air Oil Separator

Proper installation and regular maintenance are crucial for the efficient functioning of the Ingersoll Rand Air Oil Separator. Following the manufacturer's guidelines and recommended maintenance schedules help ensure optimal performance and longevity of the separator. Regular replacement of the separator element is necessary to maintain its filtration efficiency.

6. Applications of the Ingersoll Rand Air Oil Separator

The Ingersoll Rand Air Oil Separator finds applications in various industries, including:

- Automotive manufacturing

- Food and beverage processing

- Pharmaceutical production

- Chemical processing

- Textile manufacturing

7. Maintaining Regulatory Compliance

In many industries, compliance with air quality standards and regulations is essential. The use of the Ingersoll Rand Air Oil Separator helps industries meet these requirements by ensuring that the compressed air supplied is free from oil contamination. This is particularly crucial in the food, pharmaceutical, and medical sectors where product safety and hygiene are of utmost importance.

8. The Role of Ingersoll Rand in Air Compressor Technology

Ingersoll Rand has established itself as a leader in air compressor technology, providing innovative solutions to meet the ever-evolving needs of industries. The Ingersoll Rand Air Oil Separator is a testament to their commitment to delivering high-quality products that enhance performance, reliability, and efficiency in compressed air systems.

9. Investing in Quality for Long-Term Benefits

While the initial cost of an Ingersoll Rand Air Oil Separator may be higher compared to generic alternatives, the long-term benefits and reliability it offers make it a worthwhile investment. By choosing Ingersoll Rand, you can be confident in the performance and durability of the separator, ensuring uninterrupted operations and reduced downtime.

10. Conclusion

The Ingersoll Rand Air Oil Separator is a critical component for maintaining the purity of compressed air in various industrial applications. By efficiently separating oil aerosols, the separator enhances equipment performance, extends equipment lifespan, improves product quality, and promotes energy efficiency. Investing in the Ingersoll Rand Air Oil Separator ensures compliance with regulations, protects equipment, and contributes to the overall success of your operations.